Chimney Air Emission Monitoring

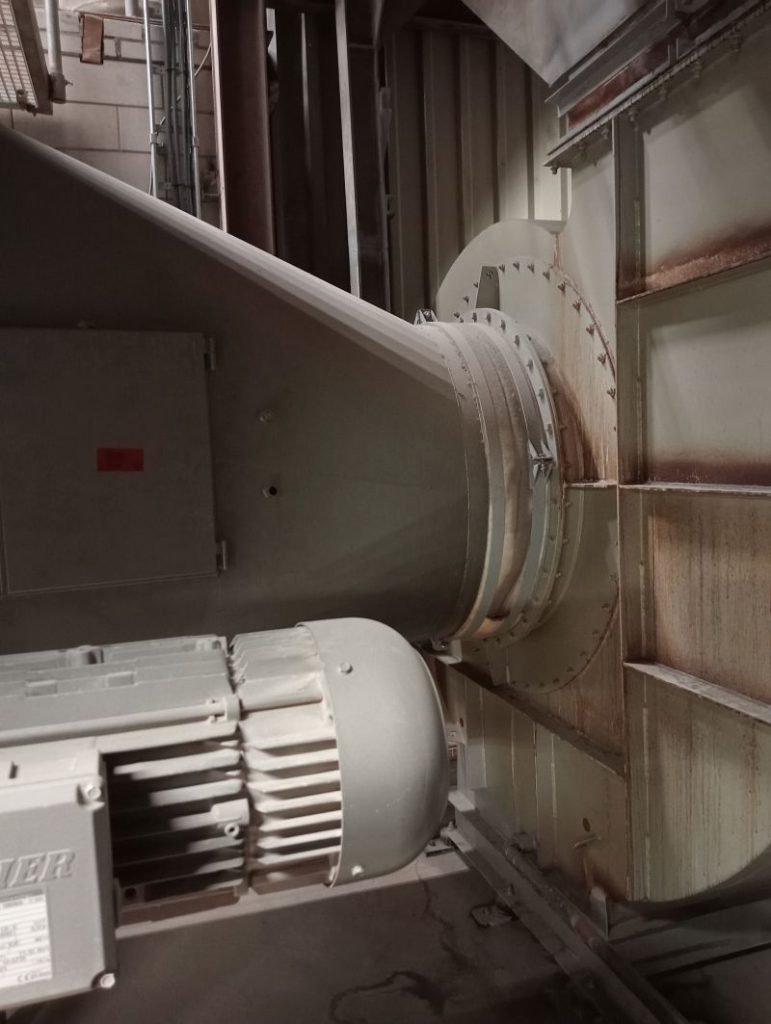

Last week, we performed a chimney emission measurement at an asphalt plant in the Netherlands. With the increasing reuse of asphalt, the emission of gases is also increasing.

Interested? Call 0031 6 200 17 111 or e-mail me via remo.natali@vanweesinnovations.com

Peter van Wees has developed a patented technology with which he captures 99.99% of all ultrafine particles – no more odor – and over 99% of all gases. This way, asphalt plants can operate circularly without polluting the environment.

In this factory, we measure behind the filter in the chimney at about 15 meters high. We use the best measuring equipment and special ‘spheres’. These bulbs are under negative pressure. A hose is connected to the valve, which is fed through a small opening into the chimney. After opening the valve, the bulb fills up from -3 bar to 0. I then close the valve, pack the bulb properly and send it to the laboratory for analysis. As a backup, I repeat the procedure with a second bulb.

It is the first step towards a cleaner environment; the environment in which we live. With VWI technology, you can reduce almost any kind of emissions to practically zero. How would you sleep at night knowing that you operate the cleanest factory in the Netherlands? And what could the environmental service employee report with 0 on his display?

What is Chimney air emission monitoring?

Chimney air emission monitoring is the process of measuring and analyzing the chemical and physical characteristics of emissions released into air through a chimney.

This has four advantages:

- Environmental protection:

Monitoring chimney air emissions helps to ensure that harmful pollutants, like NOX, SO2 and particulate matter (UFP) are not released into the air above allowed levels in order to protect the environment and human health. - Compliance with regulations:

Chimney air emission monitoring is required by environmental regulations to ensure that industries and facilities are meeting obligations for controlling air pollution. - Improving efficiency:

Monitoring chimney air emissions can help identify inefficiencies where the production process can be optimized in order to reduce emissions. - Building public trust:

By monitoring and reporting chimney air emissions, production facilities demonstrate their environmental responsibility, transparency with public trust as a result.